Effective Particle Coating and Solvent Reduction

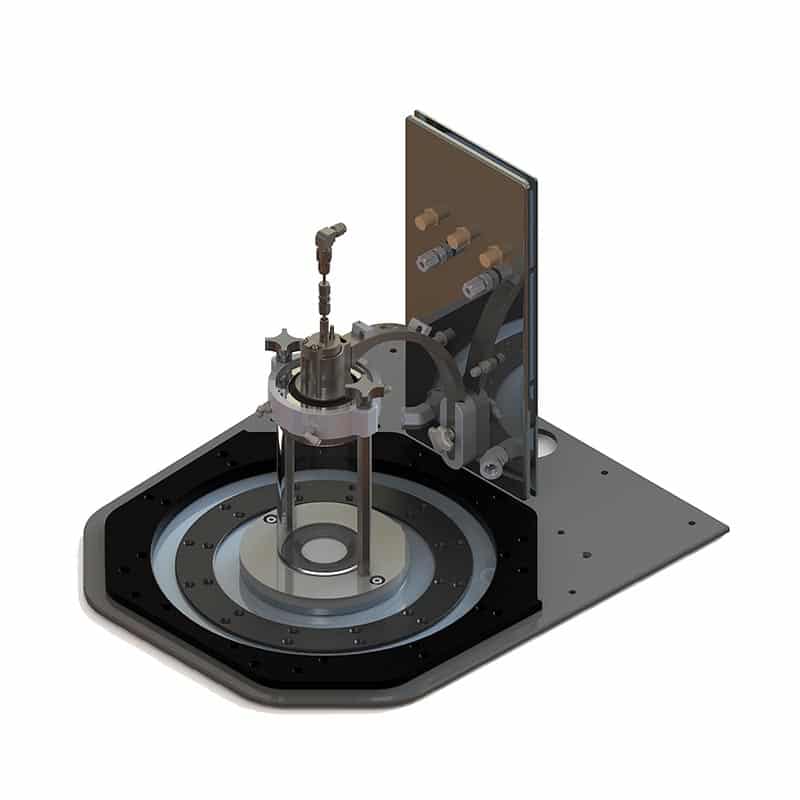

Designed to expand the LabRAM II capabilities, the Resodyn Spray Coating System mounts to the resonator plate of a LabRAM II, 2.2 lbs. (1,000 gram) capacity device. Spray system peristaltic or syringe pump options supply highly controlled stream of material to an ultrasonic nozzle, adding a spray coating feature to LabRAM II capabilities. Utilizing the existing ResonantAcoustic® Mixing (RAM) platform, the bed of dry ingredients is fluidized while the Spray System’s ultra-sonic nozzle creates a mist, coating particles without wetting, and LabRAM II’s vacuum system maintains an appropriately dry environment, drawing off unneeded solvents.

Key Processing Capabilities

- Improve uniformity of coating and mix quality concurrently

- Take advantage of RAM mixer performance to coat dry powder ingredients and reduce solvent use

- Coats dry / powder mix ingredients in standard 16 fluid ounce mixing vessel

- Meters a constant and precise amount of atomized liquid for consistent and homogeneous coating

Spray Coating System Features

- Suitable for intermittent or continuous operation

- Equipped with vacuum ports to assist drying

- Operated with a peristaltic and / or syringe pump

- Easy installation and operation

- Integrates with effective and efficient RAM mixing and vacuum technology

Compatible RAM Mixers

Specifications

| Item | Process Requirements | Quantity |

| Vessel and Lid | Product Vacuum (Purchased Separately) | Capable up to 26 in. Hg. |

| Acceleration | Up to 35 g | |

| Nozzle | Viscosity | Up to ~5,000 cP |

| Power | Single Phase, 110-240VAC, 15A, 50/60 Hz Power | |

| Material | Liquid | |

| Frequency | 130 kHz | |

| Mean Particle Size (Water) | 12 µm | |

| Flow Rates | 0—20 mL/min |