Advanced Processing and Development Platform

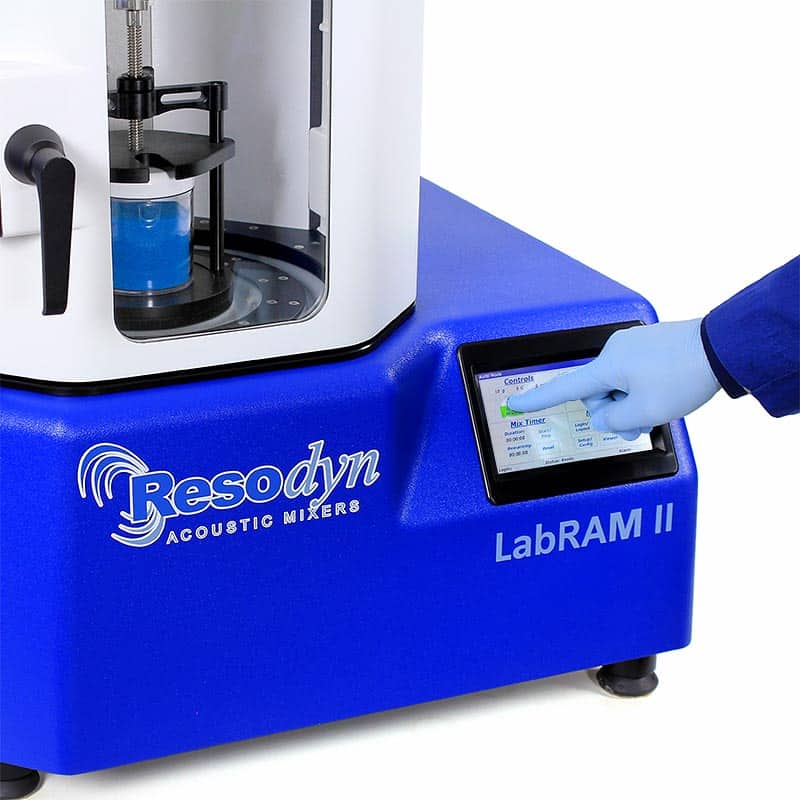

The LabRAM II’s set of design and features reflects users’ critical requirements, delivering processing speed, mixing power, and optimal parameters to scale production RAM machines. With an integrated touch-screen controlled operating system that enables recipe development and data management, and optional processing accessories including vacuum systems and temperature-controlled vessels, the LabRAM II gives users better results, improved efficiency, and new product opportunities.

Key Processing Capabilities

- Mixing and processing any combination of

- Solids/Powders – from nano-scale, and higher

- Liquids/Gases

- Viscous/Slurry materials

- Coating, Milling, Grinding processes

- On-board control of optional processing accessories

- Automatic Vacuum System

- Jacketed Vessel Temperature Control

- Spray-coating Functions

- Develop, store, and secure up to 100 recipes

- Monitor mixing parameters in real-time

- Download processing data for analysis

LabRAM II Features

- Up to 2.2 lbs (1,000 grams) payload processing capacity

- Integrated touch screen operating system

- Intense, but gentle acoustic mixing for rapid, highly repeatable, ultra-high quality results

- Fully enclosed, interlock-able acoustic mix chamber

- Height-adjustable vessel holder accepts many vessel types

- Multiple level security and access control

Available Processing Accessories Include

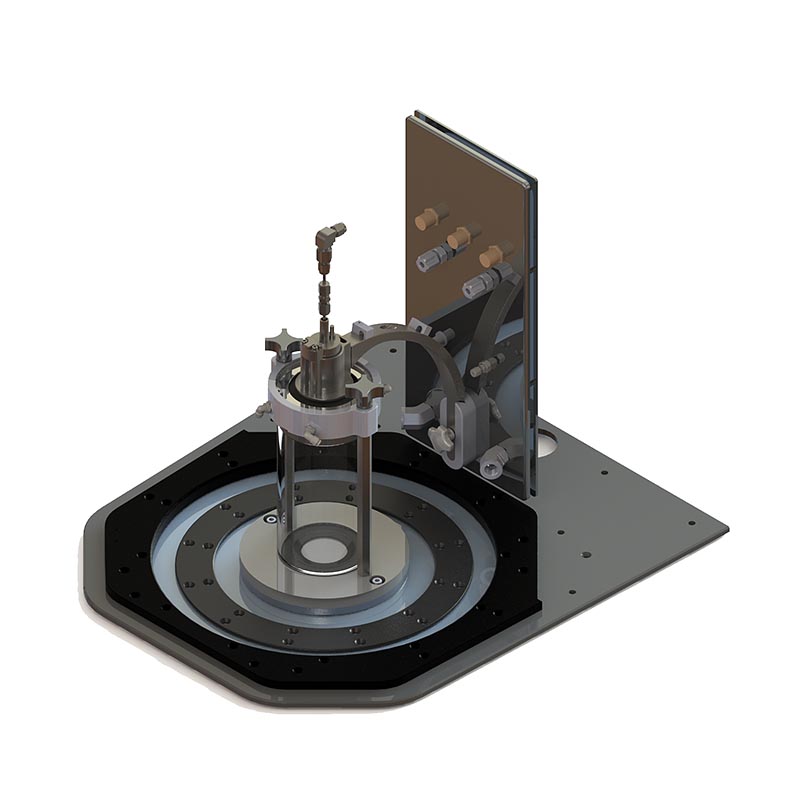

- Automatic Vacuum System

- Manual Vacuum System

- Jacketed Vessel Temperature Control

- In-vessel Spray Coating System

- Custom Components

Specifications

| General | |

| Model | LabRAM II |

| Technology | ResonantAcoustic® Mixing |

| Intended Use | Laboratory, Development, Bench-scale Batch Mixing |

| Unit Dimensions | 33″ H x 29″ W x 24.5″ D (cm: 83.8 x 73.7 x 62.2) |

| Unit Weight | 260 lbs (117.9 kg) |

| Country of Origin | USA |

| Certifications | CE Certified, UL Certification Available |

| Operating Specifications | |

| Maximum Payload Capacity | 2.2 lbs (1 kg) |

| Compatible Materials | Solids, Liquids, Slurries, High Viscosity Pastes |

| Max Vessel Acceleration | 100g at 60 Hz |

| Max Operating Noise | < 70 db at 3′ |

| Sealed Acoustic Chamber | Yes |

| Included Vessel Holder Assembly | 5″ Diameter – Adjusts for 2.5″ to 5″ High Vessels |

| Included Vessels | 1 x Polypropylene 4 oz |

| 1 x Polypropylene 8 oz | |

| 1 x Polyethylene 4 oz | |

| 1 x Polyethylene 8 oz | |

| Control Specifications | |

| Human Machine Interface | Full Color Touch Screen |

| Operating System | Proprietary On-Board |

| Programable Mix Recipe Storage | Yes |

| Data Logging | Yes |

| Remote Operation | Yes, with RAMware3 |

| Power Specifications | |

| Required Voltage at 50/60 Hz | 100-120 / 200-240 VAC |

| Current Required | 1000 watts |

| Power Cord | Region-Specific Cord Included |